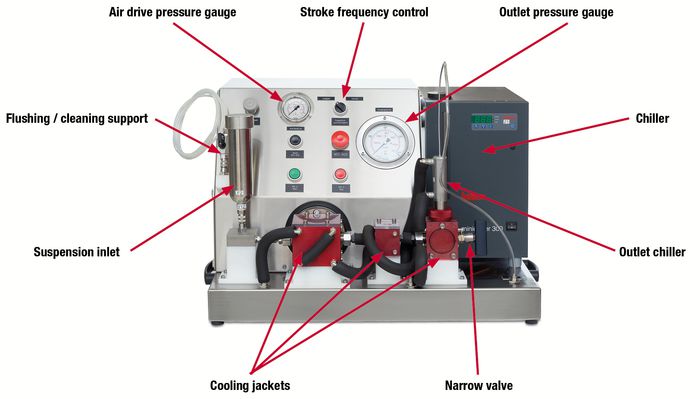

High Pressure Homogenizer Type HPL6

The Maximator high pressure homogenizer HPL6 can be used for cell disruption in the biotechnology, for the homogenizing of dairy products, disruption of cellulose in vegetables, and production of gel systems in the pharmaceutical industry.

High pressure homogenizers are used for many applications in the biotechnology, pharmaceutical, cosmetic, food, and environmental industries, where it is necessary to reach particle sizes in a nano range.

The Maximator high pressure homogenizer HPL6 is designed for energy-efficient, continuous production of superfine emulsions. The HPL6 system achieves the homogenizing effect by means of fully adjustable decompression of the liquid from max. 4200 bar to an ambient pressure.

The high pressure homogenizer uses a Maximator air driven high pressure pump to pressurise the suspension / liquid. The required pressure for the homogenizing process can be easily pre-set by means of adjusting the air drive pressure from 1 to 10 bar.

In order to achiev the best possible homogenizing results, a Maximator high pressure micrometer-needle valve is used as homogenizing valve and allows the user to adjust the gap in an extremly precise manner.

HPL6 user benefits

- Excellent flow rates at comparatively very high pressure

- Low temperature throughout entire process

- Simple and safe operation

- Very easy and fast to clean

- Quiet and low-maintenance

- Small dead space volume

- Very fast support-exchange (from sample vessel to flushing swivel)

Lagre

Lagre

Lagre